Need functionality or an eye-catching design element? Embossing delivers both!

As a busy project manager (or purchasing manager), your job is to bring together a zillion pieces and parts – and deliver the finished project on time and on budget. Turns out, your project needs an embossed or Braille nameplate, overlay, or plastic label.

If your project requires embossing (including Braille) for an equipment keypad or graphic overlay, embossing adds a tactile quality that improves user interface. If you need an attention-getting design element for your plastic nameplate or label, embossing is guaranteed to up-level the professional look – especially given our wide range of options for shapes, patterns, textures, and library of dies.

Now you may be thinking:

- “So many choices! We need this done right, and we need it FAST.”

- “I don’t have time to study the ADA standards for Braille.”

- “There’s no time for guesswork – we need guidance from technical experts.”

We know you’re crazy-busy, and we’re here to help! Scroll down for ideas, insight, and technical advice.

STEP 1: Learn about embossing options

What is the difference between embossing and debossing? What is blind embossing? Come up to speed with this quick reference guide.

Embossing: The die is pressed into the underside of the material; this creates a raised image when your nameplate or label is viewed from the front. We can combine several types of embossing such as domed, rim, and multi-level.

Debossing: The die is pressed into the face of the material, creating a depressed image instead of a raised image.

|

Project Manager’s Reference Guide: Embossed & Braille Nameplates, Overlays, Plastic Labels

|

||

|

Type of embossing |

Profile sketch |

Description |

|

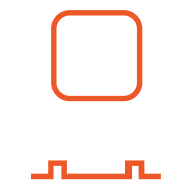

Rim embossing (including rail) |

|

Here, the outline of the graphic element – the logo, button, or other shape – is raised. Rail embossing has two lines, like a railroad track.

|

|

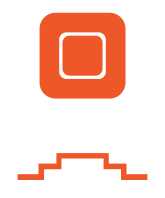

Pillow embossing (including domed) |

|

With this type of embossing (also called pad), the entire surface of the logo, button, or design element is raised. The domed emboss is shaped like a raised dome.

|

|

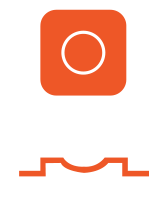

Multi-level embossing |

|

Let your creativity soar! Multiple levels provide a highly tactile, uber-professional product.

|

|

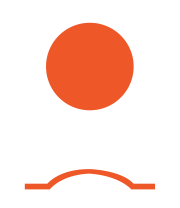

Blind embossing |

|

“Blind” refers to the fact that no ink is used on the embossed (or debossed) graphic element. For example, the logo on a plastic label could be blind embossed into the label material; the tactile quality up-levels the professional look-and-feel.

|

|

Braille |

|

A type of embossing, Braille is used on a wide variety of nameplates, keypads, overlays, and plastic labels for all types of industries. You can rely on NFI Corp.’s technical expertise to ensure your project is ADA compliant.

|

STEP 2: Need a Braille sign? Don’t guess on ADA requirements

As you know, designing an ADA-compliant Braille sign cannot be a guessing game. Plus, you may know that the ADA Standards for Accessible Design document is overwhelming.

Here are just few examples:

- Some signs require Grade 1 Braille, while some require Grade 2 Braille. (Grade 1 is a nearly direct transcription of printed English. Grade 2 relies on abbreviations and contractions.)

- Text must be a certain height with a certain degree of contrast for readability

- Pictograms are optional, but they must meet a set of criteria

- Some information does not need to adhere to the standards, such as directions

Don’t guess on ADA requirements and risk getting them wrong. The time and hassle involved in reworking Braille signage could put your production schedule at risk. Instead, call NFI Corp. You can rely on our technical expertise to create ADA-compliant Braille nameplates, graphic overlays, and plastic labels.

STEP 3: Get a prototype of your embossed nameplate, overlay or plastic label

NFI Corp.’s Prototype Program offers rapid product development with guaranteed fast turnaround. You’ll be able to test the form, fit, and function in just days.

Our Prototype Program features:

- Individualized support from our skilled design and pre-press team

- Rapid development (3-5 day delivery)

- Small quantity production (10 pieces)

- Testing without the costs of full production or tooling

Need a custom embossed or Braille nameplate, overlay or plastic label?

Get it done right – and get it fast – with no guesswork.