Graphic Overlays: 6 questions to ask when selecting materials and finish options

Will your Graphic Overlay be used in a sterile medical facility or a gritty manufacturing environment? Or will it be outdoors, exposed to sunlight and the elements and used by workers wearing heavy leather gloves? No matter the environment and user-interface requirements, your Graphic Overlay must offer maximum protection, reliability, usability, and lifespan. That’s why it’s critical to select the right materials and finish options.

The right materials + finish options will ensure a high-performing Graphic Overlay.

Before you make a choice, you must first understand the available options. To determine the right materials and finish options for your project, you’ll need to match the performance characteristics to your application’s demands and physical environment. Here are 6 questions to discuss with Graphic Overlay manufacturers such as NFI Corp when designing your Graphic Overlay.

1. Which material is better?

As you might guess, the answer is “It depends on your application.” Here are a few points on these two tough materials. We encourage you to contact NFI Corp to discuss these materials and determine which is best for your application.

- Polycarbonate – Available in various thicknesses and surface finishes, polycarbonate is a high-performing material with excellent mechanical properties. Polycarbonate is optically clear at any thickness and provides a crisper emboss. Also known as PETG or Lexan, polycarbonate overlays are easy to die cut, print, and texture. An excellent choice for a wide variety of applications, polycarbonate is resistant to heat, moisture, and abrasion. However, it may show signs of wear after 100,000 actuations. If the environment is subject to chemicals, a hard coat should be used for protection. Polycarbonate is lower in cost than polyester. Most users prefer the look of polycarbonate overlays versus polyester.

- Polyester – This resilient material offers superior resistance to chemicals and harsh environments. (Perfect for construction, industrial, and military applications.) It’s offered in various thicknesses with a range of textures and anti-glare finishes. Polyester is better suited for use with tactile feedback switches, because it can withstand a greater number of actuation. In fact, it shows no sign of wear after 1,000,000 actuations.

2. What types of finish options are available?

The finish options you choose should add protection, increase durability, and enhance the usability of your Graphic Overlay.

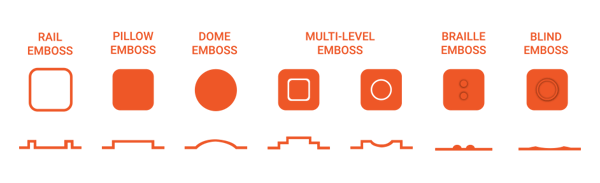

- Textured surfaces, embossing, debossing – While aesthetically pleasing, these options can directly improve the user experience.

- Matte or glossy – A gloss material can enhance the overlay’s colors. A matte finish can reduce glare issues and doesn’t readily show fingerprints or minor scratches.

- Window cutout and lens coating – At Design Mark, options include anti-glare (LED, VF, LCD), velvet texture (enunciator, LED), gloss or water clear (LCD), and window insert. Color dyes can be added to produce red, green, yellow, or other tinted LCD displays.

- Chemical resistant surfaces – Will your Graphic Overlay be exposed to cleaning products or industrial chemicals? If so, add “chemical resistant surface” to your design specifications. You may also want to environmentally seal or liquid seal your Graphic Overlay.

- Ultraviolet (UV) hardcoats – Both polycarbonate and polyester are susceptible to scratching. We recommend a UV hardcoating (or another hardcoat) to increase the durability of your Graphic Overlay. Of course, if your product will be used outdoors, a UV hardcoat is a must.

3. Which options enhance user interface?

When it comes to Graphic Overlay, usability is the name of the game. Textured surfaces can help users locate keys more easily, which can improve human-machine interface in low-lighting situations and other environments. Embossing (or debossing) will increase the tactile quality of your Graphic Overlay, which can directly impact usability.

4. Are there cost-saving tips?

For every Graphic Overlay, the goal is to design an easy-to-use interface, aesthetically pleasing design, and durable construction. Plus, with many projects, budget is a concern. Here are a few cost-saving tips:

- Use the minimum number of colors possible.

- Choose polycarbonate instead of polyester.

- Ensure your specs don’t call for embossing or debossing. The creation of a custom die adds cost, and this is an added step in the production process.

- Avoid tight tolerances, tiny graphics, extremely thin lines and serif fonts, which can make production more challenging and time intensive.

5. Can the manufacturer offer advice on materials and finish options – advice that is backed by a depth of experience?

Your Graphic Overlay will play a vital role in your product’s human-machine interface – and its overall success. Your Graphic Overlay must be well designed, constructed of durable materials, and be reliable over the long run. New-to-market manufacturers may not be able to offer the type of insight that comes with years (or decades) of real-world experience. Topics to discuss include:

- Expertise based on hands-on experience – How long has the company been designing and manufacturing Graphic Overlay? Are there in-house designers and engineers? Can they guide you to choose the proper materials and finish options for your application?

- Quality and communication – Is the company ISO-certified? Can you rely on clear, consistent communication? (Miscommunications can endanger your project’s delivery date.)

- Total lead time required – How much time is required for design, manufacturing, and delivery? (Offshore manufacturers require much longer lead time due to shipping.)

6. Does the Graphic Overlay manufacturer offer rapid prototyping?

In your selection process, make sure the Graphic Overlay company offers quick-turn prototyping to fully support your design process with shorter lead times. At NFI Corp, we offer a Rapid Prototyping service that offers flexibility in product development. You can get a quick-turn prototype for a fully functional prototype or a pre-production part. Learn more.

Contact NFI Corp to discuss your Graphic Overlay project with an experienced designer or engineer!