Excellence Through Precision and Continuous Refinement

In the realm of healthcare, precision and refinement are non-negotiable. NFI Corp's prototype program helps perfect medical products before mass production. This approach is paramount in the medical industry, where even the slightest enhancements can significantly affect performance and product outcomes.

Identifying and rectifying potential issues during the prototyping phase is pivotal in minimizing risks associated with large-scale production. NFI Corp's prototype program not only saves time but also saves resources by addressing needed changes early, preventing expensive fixes or recalls later on.

Tailored Solutions for Unique Challenges

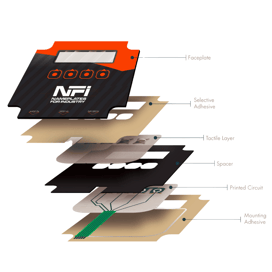

Every medical situation has unique challenges, so tailored solutions are required. NFI Corp offers various prototyping tools and materials to customize products for specific projects. Whether it's making a membrane switch or designing a product label, prototyping allows tailored solutions to meet different medical needs.

Every medical situation has unique challenges, so tailored solutions are required. NFI Corp offers various prototyping tools and materials to customize products for specific projects. Whether it's making a membrane switch or designing a product label, prototyping allows tailored solutions to meet different medical needs.

Medical devices need to pass strict tests to ensure they're safe and work well. NFI Corp's prototype program helps test designs thoroughly to meet these standards, ensuring the final product is reliable and effective.

Pioneering Medical Device Development

From conceptualization to realization, prototyping serves as a cornerstone in the development of various medical devices. It empowers engineers and designers to evaluate functionalities, ergonomics, and durability, thus ensuring that the end product aligns with the expectations of healthcare professionals and, ultimately, benefits patients.

From conceptualization to realization, prototyping serves as a cornerstone in the development of various medical devices. It empowers engineers and designers to evaluate functionalities, ergonomics, and durability, thus ensuring that the end product aligns with the expectations of healthcare professionals and, ultimately, benefits patients.

By harnessing NFI Corp's prototyping program, medical professionals and innovators can navigate the intricate terrain of medical product development with heightened confidence, efficiency, and precision, ultimately revolutionizing the healthcare landscape.